INTRODUCTION

The City of Louisville in Colorado, America was founded in 1878 and has since grown to a population of over 21,000 residents. It currently supplies its customers with raw water needs via a distribution network of over 193 km of pipeline.

A major component of the infrastructure is the ‘Louisville Raw Water Line’ pipeline. This pipeline was originally installed in 1955 and is constructed of steel sheets welded together and coated in a coal tar layer. This critical pipeline spans nearly 12km from intake to reservoir with a diameter 40cm. In the 1980’s the pipeline started showing signs of deterioration resulting in a decline in performance and capacity. Failures became more common mainly caused by external corrosion producing leaks along the length of the pipeline.

THE CHALLENGE

Today the ‘Louisville Raw Water Line’ pipeline supplies approximately one-third of the city’s water needs. In responding to the implications of potential pipeline failure, it was essential to have a clear understanding of the pipelines current condition and evaluate capability and improve performance. This required a structured and systematic process consisting of the collection and analysis of relevant data to identify anomalies such as pipe thickness, blockages, air pockets, valve status, leaks etc.

The key challenge was to utilise the best solution to integrate within the planned budget and most importantly utilise the leading technology to inform and deliver results.

The City of Louisville evaluated multiple assessment technology applications including invasive technologies such as tethered ultrasonic testing, internal robotic camera inspection and internal leak survey. Each posed limitations for the project, from operational and associated costings to accuracy and inconsistency for pipe wall assessment.

Ultimately, p-CAT TM was the technology of choice, this non-invasive, non-destructive solution provided minimal disruption along with the ability to test long distances relatively quickly and keep the pipeline essentially live during the assessment.

THE SOLUTION

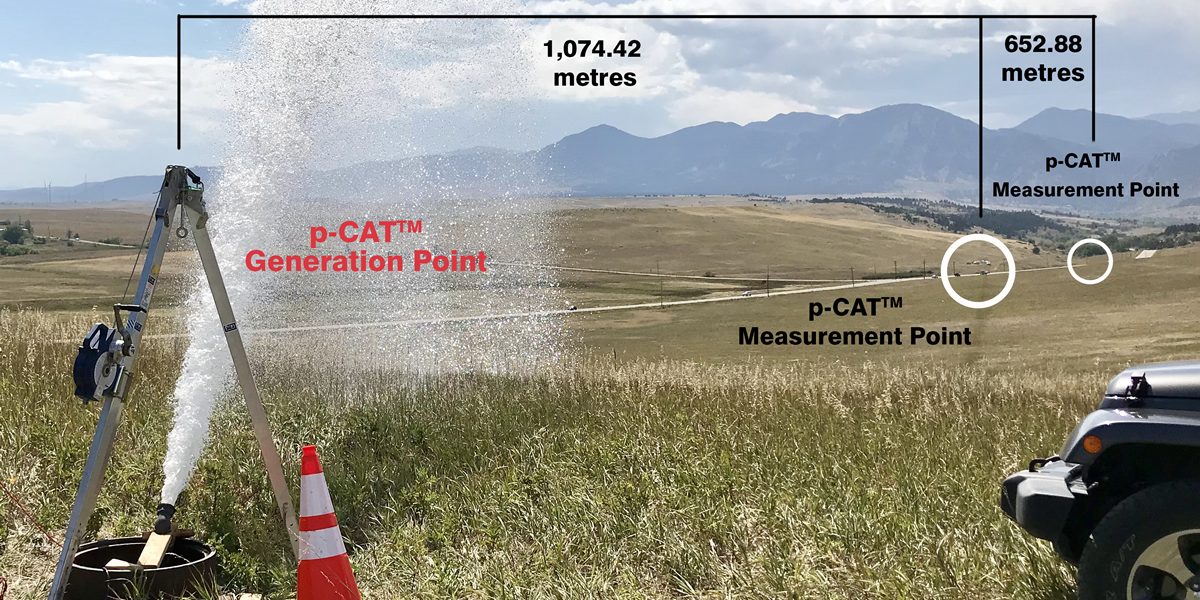

The p-CAT TM assessment used existing access points, such as air valves and hydrants to scan the pipe for the presence of corrosion or faults and to determine the sub-sectional average wall thickness. This was performed on over 4 km of the ‘Louisville Raw Water Line’ pipeline and the average remaining wall thicknesses were determined for 33 individual sub-sections within the section of interest. The presence of pipe wall damage or lining loss has a visible impact on a resultant transient pressure wave trace. This observation is the basis of this advanced technique that uses fluid transient pressure waves for detecting the sizes and locations of pipeline defects.

The results determined that varying levels of pipe deterioration had occurred based on the varying wave speeds produced along the length of the pipeline. p-CAT TM actionable anomaly data is presented with the location, fault identification and recommended actions, these anomalies are also ranked by priority; high, medium and low, for greater clarity regarding rehabilitation plans. During the pipeline signal analysis a total of five low priority anomalies and three medium priority anomalies were identified, including the presence of a possible entrained and entrapped air pocket, an offtake sealing problem and the location of potential concrete encasement or pipeline blockage. The pipeline wall condition was also identified and presented as a percentage of the assumed initial wall condition for each of the resulting 33 sub-sections.

After the implementation of the p-CAT™ technology the City of Louisville conducted the first US validation study with Dewberry Engineers Inc. (p-CAT™ has been independently validated extensively in Australia), to independently establish the validity of the p-CAT™ inspection results. In order to perform this validation study, the City excavated a 12 metre section of pipe that had previously been identified for replacement as part of a separate improvement project.

To evaluate the p-CAT™ assessment results, the higher resolution Eddy Current technology was determined to be the best method. Sensors were spaced every 63.5mm around the full circumference of the pipe, capturing a reading every 23.9mm along the entire length of an excavated 12 metre section. The results of the eddy current tests measured the average pipe wall thickness along the assessed section to be 4.343mm. For the same stretch of pipe, p-CAT™ identified the wall thickness to be 4.318mm.

Like all utilities with an ageing infrastructure, The City of Louisville faced a dilemma — it could not identify areas requiring urgent rehabilitation, it did not have enough information to justify the possible replacement of the entire sections of the pipeline and could not move from strategy to implementation.

The p-CAT TM assessment of the pipeline and its performance allowed the city to delay replacement and capital expenditure, to make informed decisions on how, when and where to allocate resources, to effectively manage the pipeline repair, rehabilitation and to guarantee the delivery of essential services.

THE TECHNOLOGY

The p-CAT TM technology is a partnership between Detection Services Pty Ltd and the University of Adelaide in Australia. p-CATTM is a non-invasive, non-destructive technology for performing pipe condition assessment. It is used to determine remaining wall thicknesses over long sections (many kilometres) of pipeline as well as detecting and locating defects such as air and gas pockets, internal blockages and restrictions, unknown connections, pipe material changes and cement matric loss from metallic, concrete and AC pipes.

p-CATTM works by analysing the partial reflection of a small, controlled transient signal that is injected into the pipeline. The signal is monitored and recorded by sensors that are temporarily installed on existing pipe fittings. The transient wave experiences partial reflection when it encounters any change in pipeline structure, including both known features of the system as well as other issues related to pipe deterioration.

p-CATTM can be applied on any pressurised fluid filled pipeline carrying potable, raw or wastewater and is cost effective, locating defects within the pipeline and limiting repairs and replacements to only the sections in need of attention.

For an overview of the p-CATTM technology for Condition Assessment, click on the following video link https://pia-global.com/technologies/p-cat/

While p-CAT TM has been extensively and independently validated, the technology was

first introduced to the US market in 2017 and to date, is the most comprehensive

and advanced solution for long distance pipelines.