Upgrading pipeline infrastructure is a never-ending task, and with hundreds of assets to consider, how can utilities determine where to prioritise their resources? Manually inspecting every single asset is a colossal undertaking for utilities. The consequences of pipeline failure can be catastrophic.

Well-maintained assets are integral to delivering essential services. However, with competing priorities, budget restraints and workforce limitations, utilities will always be faced with the question, when is the right time to repair or replace ageing pipelines?

According to PIA Chief Executive Officer, Chris Evans, utilities need access to as much information as possible to optimise their resources. “The issue is knowing where to start, knowing which assets are in poor condition and what the consequences of failure are for these pipelines,” he said.

“The cost of failure is significantly more than the cost of replacement in most instances. Pipelines don’t always fail catastrophically, but when a major burst occurs it’s not only the repair that can be costly, the impact on the environment and customers can be quite profound.”

Carrying out preventive maintenance or refurbishment works is crucial to avoid disaster; however, sending team members out to manually inspect every single asset is a colossal undertaking. The historical approach was to carry out a rolling program of pipeline inspections, which starts with a desktop assessment to understand where the key risks areas are before using that information to decide where to carry out inspections. These inspections traditionally relied on invasive methods, such as cutting the pipe, sending a camera down or digging around it to look at the coating.

“The cost of failure is significantly more than the cost of replacement in most instances. Pipelines don’t always fail catastrophically, but when a major burst occurs it’s not only the repair that can be costly, the impact on the environment and customers can be quite profound.”

Because these methods are unable to provide detailed information about the scope of the deterioration, a damaged pipeline would often be replaced from start to finish – at a huge cost to the community and the environment.

“The issue is that pipelines don’t fail uniformly; they don’t deteriorate all the way across their total length,” Mr Evans said. “If a utility had a way of using X-ray vision to look at this pipeline and identify just the smaller sections that are showing signs of deterioration, then rather than replace 5km of pipeline, they may identify during a condition assessment that only a few sections may need replacing or monitoring.

“By having a well-thought-out, well-informed condition assessment program, utilities can start thinking about where pipelines are likely to fail and the associated consequences, and then be more surgical about their refurbishment strategy.”

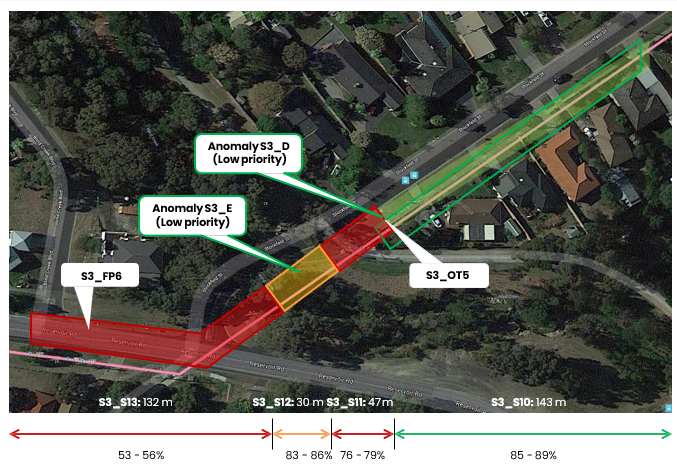

A defined section identification pipeline survey.

A solution in the pipeline

To find a solution, Detection Services and the University of Adelaide teamed up to develop p-CAT Nexus, a non-invasive and non-destructive pipeline technology. “We now use p-CAT Nexusas a long-range reconnaissance tool to identify specific sections of a pipeline that are showing signs of distress or anomalies that could accelerate failures,” Mr Evans said. “Then before the utility decides to go and dig that piece of pipe, if the pipeline is metallic, we can use our magnetic flux leakage (MFL) tool, p-CAT MFL, to give the pipeline almost like an MRI so we can see the very highest levels of corrosion inside and outside the pipe.” For assets that can’t meet the material, pressure or sizing requirements of p-CAT Nexus, PIA employs p-CAT Glide, a baseball-sized free-floating multi-sensor system.

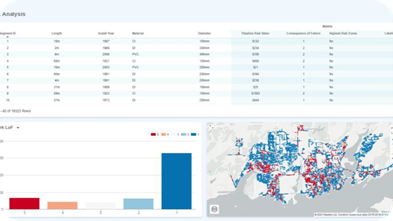

“We use the p-CAT Glide tool to look for things like leak detection on long-range pipelines, to map sediment depth, and also provide pipe alignment information,” Mr Evans said. Another technology that PIA has embraced, Rezatec, takes condition monitoring quite literally out of this world. Rezatec uses geospatial artificial intelligence – information taken from European Space Agency satellites – to map and monitor critical assets. “It’s a really smart technology, and it takes all the pipeline history, failure histories, condition and material, puts that into a database, and then builds a threat and consequence matrix,” he said.

“Rezatec provides a retrospective analysis, so it looks back over five years of history from the satellite network and then is able to track ground movement and vegetation density. And when you build all that information together, you can start providing a risk profile or a consequence of failure profile and predict where things are starting to go astray.”

Geospatial AI for clean water pipeline risk monitoring

While embracing new technologies is a core part of Detection Services’ ethos, Mr Evans said ensuring the team provides the right technology to get the right outcome is the top priority. “We try and be agnostic in terms of the solutions. Rather than try to push a round peg into a square hole with only one tool, we look for the best outcome for the client and have a large portfolio of suitable technologies,” he said.

“We’re very passionate about pipeline condition assessment, and we’re also passionate about innovation and developing our technologies to meet the market as an Australian-led business. “By working with PIA, every dollar is put back into the Australasian economy, and we provide ongoing support to various research projects in Australia to develop innovative and sustainable solutions for the water industry.

“We put a lot of investment into this solution to meet the demands of utilities, because before we had things like p-CAT Nexus people had to dig around pipes and hope for the best, or risk inserting equipment into pipelines. Now there’s a better way of doing it, and that’s been developed here in Australia.

Published in Utility Magazine 2024